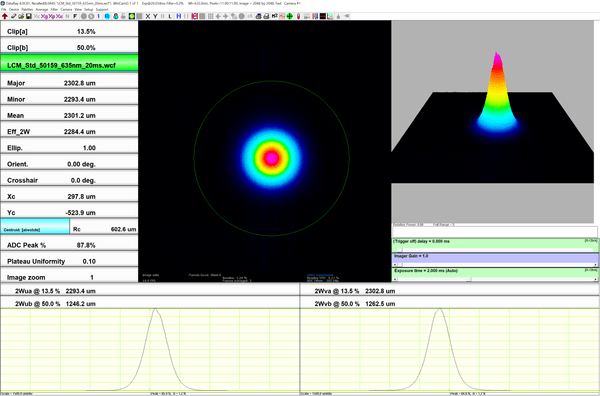

Visible Laser Beam Profiling

For profiling visible sources, you can use several of our ISO 11146 compliant beam profiling cameras or scanning slit beam profilers. The optimal product for your application will depend largely on the size of the beam and whether the beam is CW or pulsed.

Larger visible beams

For larger beams, a camera-based system is recommended.

CW/quasi-CW beams

Use a BladeCam2-XHR (beams ≥ 32 μm), WinCamD-LCM (beams ≥ 55 μm), or TaperCamD-LCM (beams ≥ 125 μm) beam profiling camera.

Pulsed beams

Use a WinCamD-LCM (beams ≥ 55 μm) or TaperCamD-LCM (beams ≥ 55 μm) beam profiling camera. These cameras have a global shutter and support TTL triggering.

Smaller visible beams

For smaller beams, camera- or scanning-slit based systems are a good solution.

CW/quasi-CW beams

Use a Beam'R2 or BeamMap2 (beams ≥ 2 μm) scanning slit beam profiler.

Pulsed beams

We recommend a WinCamD-LCM with a microscope objective or DataRay's Industrial Laser Monitoring System; these both support TTL triggering and very small beam sizes.

If you’re unsure which product is most suitable for your application or have the need for something custom, please contact us.

Have questions or need help identifying the right solution for your application?